Industrial wastewater treatment, process water treatment, sludge treatment, energy recovery and water reuse.

The challenge

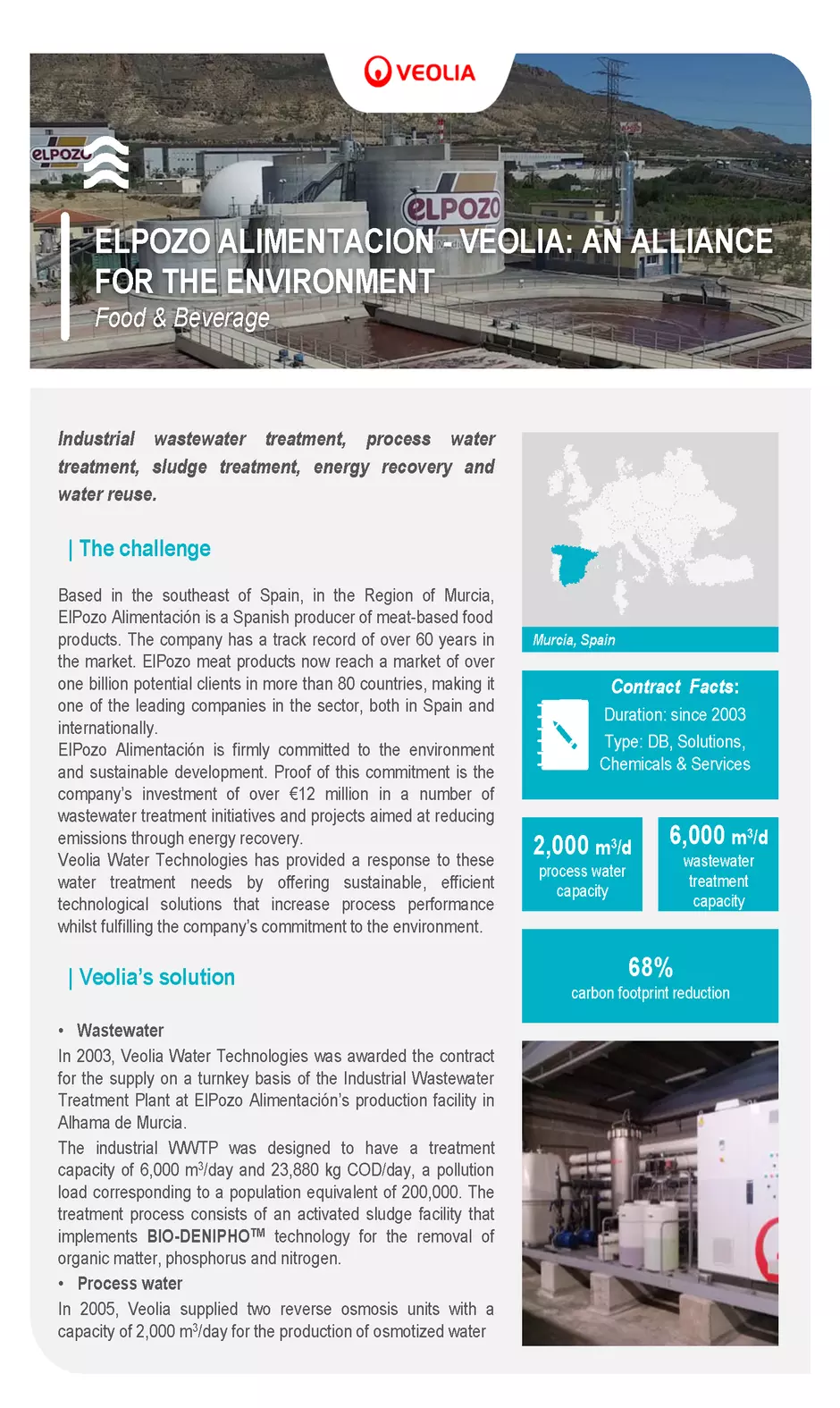

Based in the southeast of Spain, in the Region of Murcia, ElPozo Alimentación is a Spanish producer of meat-based food products. The company has a track record of over 60 years in the market. ElPozo meat products now reach a market of over one billion potential clients in more than 80 countries, making it one of the leading companies in the sector, both in Spain and internationally.

ElPozo Alimentación is firmly committed to the environment and sustainable development. Proof of this commitment is the company’s investment of over €12 million in a number of wastewater treatment initiatives and projects aimed at reducing emissions through energy recovery.

Veolia Water Technologies has provided a response to these water treatment needs by offering sustainable, efficient technological solutions that increase process performance whilst fulfilling the company’s commitment to the environment.

Veolia’s solution

- Wastewater

In 2003, Veolia Water Technologies was awarded the contract for the supply on a turnkey basis of the Industrial Wastewater Treatment Plant at ElPozo Alimentación’s production facility in Alhama de Murcia.

The industrial WWTP was designed to have a treatment capacity of 6,000 m3/day and 23,880 kg COD/day, a pollution load corresponding to a population equivalent of 200,000. The treatment process consists of an activated sludge facility that implements BIO-DENIPHOTM technology for the removal of organic matter, phosphorus and nitrogen. - Process water

In 2005, Veolia supplied two reverse osmosis units with a capacity of 2,000 m3/day for the production of osmotized water to feed the steam boiler and the evaporative condensers, as well as for other uses at the plant. Moreover, since these units went into operation, the Spanish subsidiary has also been entrusted with the provision of technical assistance and HydrexTM chemical products for the membrane processes.(4.000 Hydrex Range for RO applications (Hydrex 4102, 4202 and 4301) anti-scalants and products for plant cleaning and maintenance). At the end of 2015, Veolia’s Spanish subsidiary was awarded a further contract to supply a standby reverse osmosis unit to deal with additional production requirements. - Sludge treatment

In 2011, ElPozo Alimentación once again placed its trust in Veolia in order to address a scenario of increased production. This time, the initiative consisted of remodelling the pre-treatment process to deal with higher organic loading in the wastewater as a result of the increase in production, which rose from 8,000 to 12,000 pigs processed per day, meaning that the industrial WWTP went from a capacity of 23,880 kg/COD per day to 42,000 kg/COD per day (population equivalent of 350,000).

The work also included enlarging the sludge line through the construction of two 3,050 m3 anaerobic digesters and the installation of a cogeneration system for the production of 800 kW of electricity for self-consumption at the WWTP, and 400 kW of thermal energy to heat the sludge during the digestion process, without the need for any other fuel. These two digesters feature an innovative design that enables a reduction in the construction and operating costs of the facility, in addition to improving plant performance and the quality of biogas produced. Apart from using this energy, the digester also enables a reduction of 45% in sludge volume, with consequent cost savings in treatment and final disposal. - Energy recovery

At the end of 2014, with the aim of maximising the use of the biogas produced in the anaerobic digesters, Veolia undertook the task of modifying the gas line at the industrial WWTP to enable the excess biogas produced at the plant to be availed of. Some of the biogas is used to heat the sludge in the digesters and the remainder is sent to a new boiler to generate 5,000 kg/h of steam, with a consequent saving in natural gas.

The scope of the contract also encompassed extending the piping network, the installation of a new gas flare and the installation of a new biogas desulphurisation unit that implements Veolia’s SulfothaneTM technology, as a preventive measure to protect the facilities against corrosion. - Towards circular economy

In addition to energy recovery, which has also enabled the carbon footprint of the factory to be reduced by around 68%, ElPozo Alimentación has also undertaken a number of water reuse initiatives. These actions have enabled a considerable reduction in water consumption per pig processed and this ratio is now amongst the lowest in the sector in Europe.

The benefits

- Energy production: 800 kW of electricity for self-consumption at the WWTP.

- Carbon footprint reduction: ~68%.

- Sludge volume reduction: 45%.

- Consequent cost savings

VEOLIA’S PURPOSE: committing to a multifaceted performance

COMMERCIAL

- Reduction in the construction and operating costs of the facility.

- Improving plant performance.

- Carbon footprint reduction.

ENVIRONMENTAL

- Preserving & optimising resources: water, natural gaz.

- Prevent pollution - 42,000 kg/COD per day

- Energy recovery.