100% Biogas Energy Recovery. Using sludge-sourced biogas to produce steam.

The challenge

When new regulations required Bonduelle to build a wastewater treatment plant for its food processing factory in Békéscsaba, Hungary, the company turned to Veolia, whose specialists suggested a solution using sludge-sourced biogas to produce steam.

As Veolia exploits the biogas successfully in Nagykőrős, Bonduelle decided to use biogas also in Békéscsaba:

- Recover available biogas produced by a wastewater treatment plant with UASB technology

- Improve energy efficiency

- Optimize energy costs which challenges solve the inventions using biogas

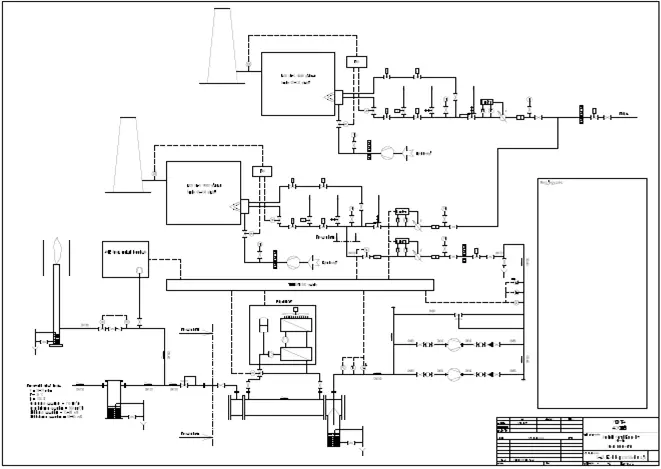

Veolia’s solution

- Renovation of the energy plant: 2 boilers in Békéscsaba

- Adaptation of one of existing boilers for the combustion of biogas

- Biogas parameters:

- Pressure: 23-27 Mbar

- Temperature: 35° C

- Production of steam at 180° C, 10 bar

- Flexibility to adapt to seasonal nature of production

The benefits

- Greener steam supply

- Average 16% reduction in energy costs (€100k/year)

- Biogas is cheaper by 20% than natural gas

- Continuous and secure supply of steam